Learning Steel Dealing With: Methods for Superior Building

Mastering steel taking care of is a fundamental element of building and construction that directly affects the security and longevity of concrete frameworks. By recognizing the details of accurate placement, the ideal use devices, and typical mistakes to prevent, experts can considerably enhance overall job end results. Moreover, adhering to ideal security practices not only safeguards workers however additionally adds to the stability of the framework itself. As we check out these techniques in greater information, the ramifications of understanding this vital skill become significantly obvious, increasing inquiries regarding exactly how these methods can change building and construction techniques.

Recognizing Steel Correcting Basics

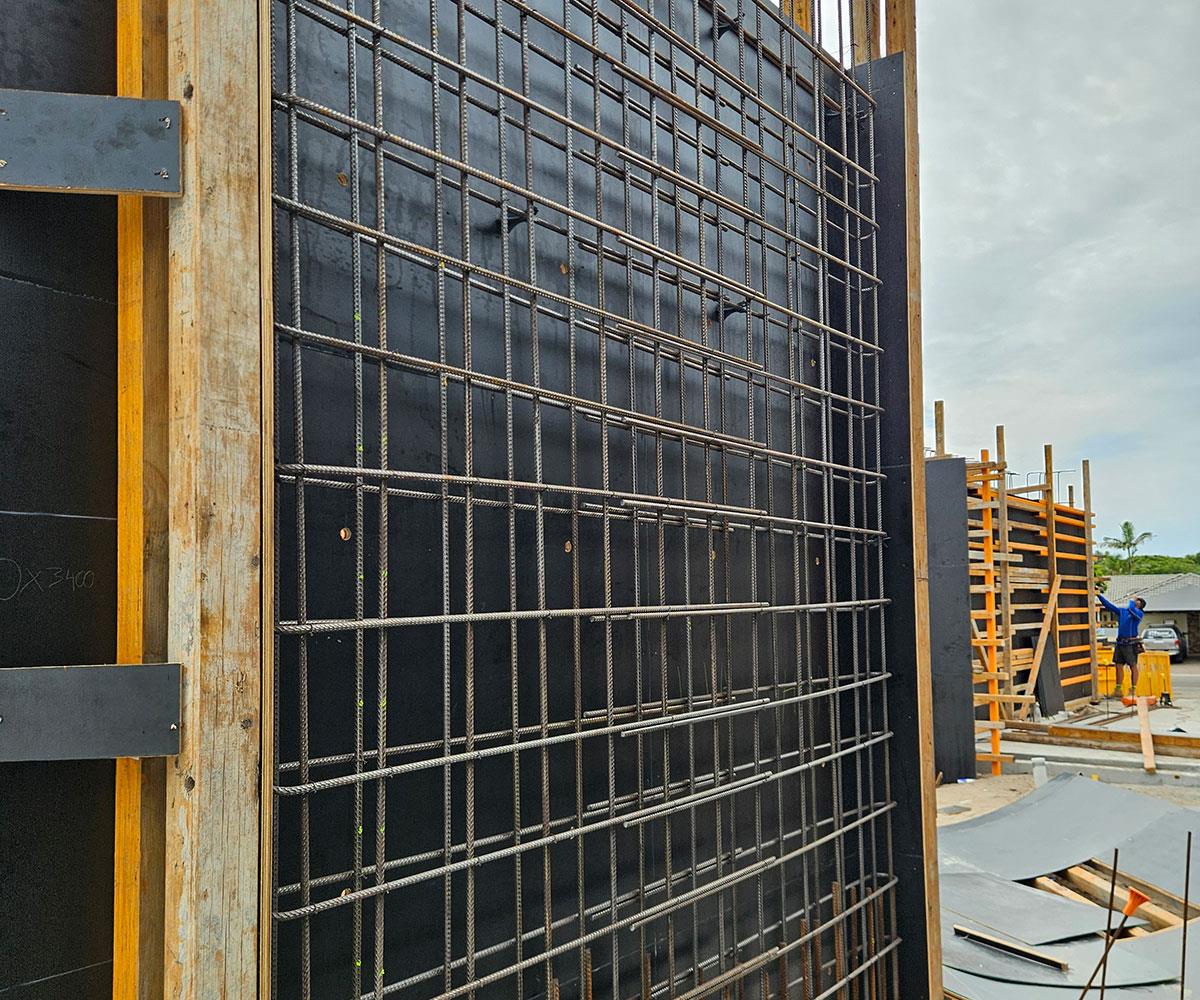

Steel taking care of, a necessary part in the building sector, entails the positioning and securing of steel support bars (rebar) within concrete structures. This procedure is crucial for making sure the architectural stability and toughness of concrete elements, as rebar considerably boosts tensile strength, which concrete does not have.

Understanding the fundamentals of steel dealing with starts with acknowledging the various kinds of rebar and their specifications, consisting of covering, diameter, and quality. Rebar is usually made from carbon steel and is available in different dimensions, which are selected based on the architectural needs of the task.

Moreover, the usage of proper lapping lengths and anchorage methods adds to the total stability of the concrete framework. It is necessary for steel fixers to stick to safety requirements and finest methods throughout the setup procedure, making certain not only the success of the task however likewise the security of all workers involved.

Vital Tools and Tools

Effective steel dealing with relies greatly on the right devices and equipment to make sure precision and effectiveness in the setup procedure. Key devices include rebar cutters, which are vital for making exact cuts in different sizes of steel bars, and rebar benders that supply the necessary angles for appropriate positioning. Additionally, a top quality set of pliers, specifically tie wire pliers, is critical for securing rebar with tie wire.

Measuring tools, such as measuring tape and laser degrees, facilitate accurate format and positioning, while a durable assortment of clamps and vises aids in holding the rebar ready throughout setting up. Safety equipment, consisting of gloves and safety glasses, can not be ignored, as they shield workers from prospective dangers associated with steel handling.

For larger tasks, spending in mechanical devices like rebar tying equipments can substantially boost efficiency. Last but not least, appropriate storage solutions, such as shelfs or bins, help organize products and preserve a safe functioning atmosphere. By making use of these important devices and devices, steel fixers can boost their workflow, making sure that structural honesty and building timelines are met precision

Strategies for Accurate Positioning

One reliable technique is using design templates or marking overviews to establish accurate locations for steel bars. These guides ought to be made from durable products to withstand the rigors of construction and need to be inspected against architectural drawings to confirm precision. Additionally, using laser levels can greatly improve alignment and altitude accuracy.

Moreover, preserving correct spacing between reinforcements is essential. This can be achieved by using spacers or chairs that are designed to hold steel bars in position at the called for distance from the formwork.

Normal evaluations throughout positioning should be conducted to guarantee conformity with task requirements. Any kind of deviations have to be dealt with right away to protect against structural weaknesses.

Lastly, partnership with other trades is important, as clear interaction can protect against placement errors that might develop from contrasting building and construction activities. By carrying out these strategies, steel fixers can substantially add to the total quality and security of the building and construction project.

Usual Mistakes to Prevent

While ensuring the correct placement of reinforcement steel is essential, several typical errors can undermine the stability of the construction procedure. One constant error is poor spacing between steel bars. Not enough spacing can lead to blockage, which can compromise concrete flow and bonding, eventually impacting architectural stamina.

One more usual mistake involves neglecting to correctly protect the reinforcement bars during positioning. Failing to appropriately connect or sustain the steel can lead to imbalance, specifically when concrete is poured, resulting in structural weaknesses. Furthermore, overlooking the needed cover thickness commonly causes early rust of the steel, lessening the durability of the structure.

Improper cutting and bending of rebar is one more risk that can lead to stress and compression concerns within the concrete. It is vital to adhere to exact specs to keep the desired load-bearing capability.

Finally, poor assessment before concrete pouring can allow these mistakes to go undetected. Routine checks and adherence try this to create requirements are necessary to ensure that steel fixing is performed properly. By preventing these usual mistakes, construction specialists can boost the longevity and safety of their jobs, making certain a successful result.

Best Practices for Safety

Making certain the integrity of steel taking care of is not only concerning staying clear of common errors however additionally concerning applying best methods for security on the building and construction website. A detailed safety strategy ought to start with proper training and orientation for all employees included in steel fixing. Employees should be acquainted with safety and security procedures, tools usage, and emergency treatments to minimize threats effectively.

Preserving a well organized and tidy work setting is similarly important. Clear paths and correct storage of materials can significantly lower journey and fall dangers. Furthermore, carrying out robust interaction procedures, such as hand signals or radios, can prevent crashes brought on by miscommunication.

Finally, cultivating a culture of safety and security amongst employee motivates watchfulness and responsibility. Routine safety and security meetings and open discussions regarding prospective dangers will certainly advertise positive procedures and improve general safety on the construction site. By adhering to these best practices, the danger of mishaps throughout steel dealing with jobs can be substantially minimized.

Final Thought

Grasping steel fixing is crucial for making certain the architectural integrity and resilience of concrete constructions. By utilizing exact methods, using appropriate devices, and adhering to ideal practices, the quality of building and construction can get more be considerably boosted.

Grasping steel taking care of is a fundamental aspect of building and construction that straight affects the security and long life of concrete structures. By making use of these crucial tools and equipment, steel fixers can improve their process, ensuring that Read More Here architectural stability and building and construction timelines are satisfied with accuracy.

While guaranteeing the right positioning of reinforcement steel is essential, a number of usual errors can threaten the honesty of the building and construction procedure.Ensuring the integrity of steel taking care of is not just about staying clear of usual errors but also concerning applying best methods for safety on the construction site.Mastering steel taking care of is crucial for guaranteeing the structural integrity and resilience of concrete buildings.

Comments on “Efficient On-Site Steel Reinforcement Installation for Quick and Reliable Builds”